Revolutionising Manufacturing: Top Industry 4.0 Investment Plays

- MBIM

- Apr 12

- 5 min read

Updated: Apr 24

Industry 4.0, the Fourth Industrial Revolution, is reshaping manufacturing through converging advanced technologies that create smarter, interconnected, and data-driven production systems. Its complex ecosystem comprises multiple segments that work together to drive efficiency, innovation, and sustainability. Below, we outline the key segments of Industry 4.0 and identify investment opportunities with high growth potential.

1. Internet of Things (IoT) and Industrial IoT (IIoT)

IoT and IIoT involve interconnected devices and sensors that collect and share real-time data across machines, factories, and supply chains. These systems enable monitoring, predictive maintenance, and process optimisation, forming the backbone of smart factories.

Example solutions: Low-Power IoT Sensor Networks

IoT sensors are already transforming farming by delivering real-time insights into soil conditions, weather, and livestock health. For instance, soil moisture sensors help farmers water crops efficiently, while temperature and humidity sensors monitor conditions to prevent pests or diseases. These tools also support precision agriculture, enabling targeted use of fertilisers and pesticides, which cuts costs and benefits the environment. Additionally, IoT sensors can integrate with automated systems - think smart irrigation or livestock feeding - and provide data for smarter decisions, boosting yields and turning traditional farming into a high-tech operation.

Small and medium enterprises (SMEs) often lack the resources for large-scale IoT deployments. Investing in companies developing low-cost, low-power IoT sensor networks tailored for SMEs can tap into an underserved market. Using technologies like LoRaWAN for long-range, low-energy communication, these solutions allow smaller manufacturers to monitor equipment or track inventory affordably, democratising Industry 4.0 adoption.

2. Artificial Intelligence (AI) and Machine Learning

AI and machine learning analyse vast datasets to optimise manufacturing processes, predict equipment failures, and enhance decision-making. Applications include quality control, demand forecasting, and adaptive production adjustments.

Example solutions: AI-Powered Process Simulation for Custom Manufacturing

Custom manufacturing requires precise process planning, such as bespoke machinery or tailored consumer goods. Investing in AI platforms that simulate and optimise production processes for high-mix, low-volume runs can address a niche need. These tools could use generative AI to model workflows, reducing setup times and waste for manufacturers producing unique or small-batch products.

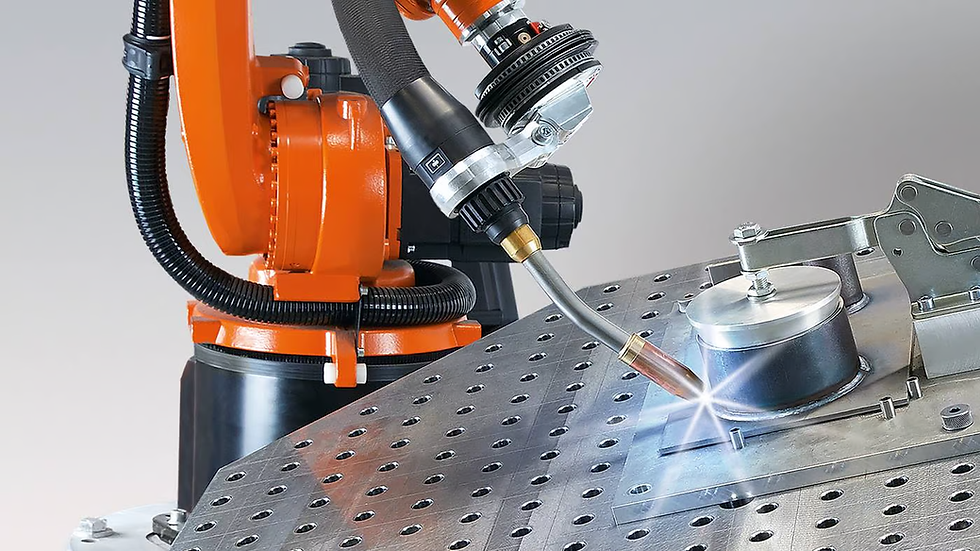

3. Robotics and Automation

Robotics, including collaborative robots (cobots), automate repetitive tasks like welding, assembly, or material handling. Automation systems integrate with other technologies to streamline production and improve precision.

Example solutions: Modular Cobot Tooling Systems

Cobots are versatile but often require specialised end-of-arm tooling for tasks like welding or gripping. Investing in companies creating modular, plug-and-play tooling systems that allow cobots to switch tasks quickly can enhance their flexibility. These systems could cater to industries with diverse production needs, such as electronics or furniture, enabling rapid reconfiguration without costly downtime.

4. Big Data Analytics

Big data analytics processes the massive datasets generated by IoT, robotics, and other systems to uncover insights, optimise operations, and drive predictive capabilities. It’s critical for real-time decision-making and quality assurance.

Example solutions: Real-Time Quality Control

Big data solutions monitor production lines in real-time, catching defects early. By analysing data from sensors and cameras, manufacturers can detect anomalies and take corrective action before faulty products are produced.

In food production, IoT sensors continuously track temperature and pH levels during processing (e.g., pasteurisation or fermentation). Deviations trigger alerts, enabling operators to adjust conditions immediately to maintain product safety.

5. Cloud Computing

Cloud computing provides scalable storage and processing power for Industry 4.0 data, enabling real-time access to analytics, digital twins, and collaborative platforms across global operations.

Example solutions: Cloud-Hosted Manufacturing Execution Systems (MES)

A cloud-based MES enables manufacturers to oversee production processes remotely by providing real-time access to critical data like production schedules, inventory levels, and quality control metrics. This enhances collaboration and decision-making across multiple locations. For instance, a global automotive company could use a cloud MES to synchronise production across factories in different countries, ensuring efficiency and consistency.

6. Cybersecurity

As Industry 4.0 increases connectivity, cybersecurity protects IIoT devices, networks, and data from breaches and cyberattacks, ensuring operational integrity and trust.

Example solutions: Security for IIoT Devices

The proliferation of IIoT devices introduces significant cybersecurity risks as more devices connect to networks, the number of potential entry points for cyberattacks grows, endangering data security, operational continuity, and even physical equipment. These risks are especially pronounced for Industrial Control Systems (ICS), the critical systems that oversee and manage manufacturing, energy, and utilities industrial processes. A successful attack on ICS could disrupt production, damage machinery, or pose safety hazards, amplifying the urgency for robust security measures. Allocating capital to cybersecurity firms specialising in IIoT and ICS protection solutions represents a compelling investment opportunity within the rapidly expanding Industry 4.0 ecosystem.

7. Additive Manufacturing

Additive manufacturing produces complex parts layer by layer, enabling rapid prototyping, customisation, and reduced material waste. It’s increasingly integrated into smart production lines.

Example solutions: Additive Manufacturing Technologies

Additive manufacturing is a rapidly developing sector, driven by innovative technologies such as Fused Deposition Modelling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Other notable methods, like Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), further advance the field.

8. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR enhance training, maintenance, and design by overlaying digital information or creating immersive simulations. They improve worker efficiency and reduce errors.

Example solutions: AR-Guided Remote Maintenance Platforms

With skilled technicians in short supply, investing in AR platforms that enable remote experts to guide on-site workers through complex maintenance tasks can be lucrative. These platforms could use AR glasses to provide real-time instructions, reducing travel costs and downtime for manufacturers with distributed facilities.

9. Digital Twins

Digital twins are virtual replicas of physical assets, enabling real-time monitoring, simulation, and optimisation of equipment or processes without disrupting operations.

Example solutions: Digital Twins for Legacy Equipment Retrofits

Many factories rely on older machines lacking smart capabilities. Investing in companies creating digital twin solutions that retrofit legacy equipment with IoT sensors and simulation software can bridge this gap. These retrofits allow manufacturers to modernise affordably, extending the life of existing assets.

10. Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP)

MES and ERP systems orchestrate production and align manufacturing with business goals, integrating data from shop floors to supply chains for seamless operations.

Example solutions: MES for Circular Economy Tracking

Sustainability is a growing priority. Investing in MES platforms that track material lifecycles to support circular economy practices, such as recycling or reusing components, can meet this demand. These systems could provide data on material origins and recyclability, appealing to eco-conscious industries like automotive or electronics.

Conclusion

The Industry 4.0 ecosystem is a dynamic landscape of interconnected segments, each presenting unique investment opportunities and exciting chances for investors to align their portfolios with the technologies of tomorrow. By targeting niche, underserved areas, investors can address emerging market needs and industry challenges, yielding significant returns. present exciting opportunities for investors seeking to align their portfolios with the technologies of tomorrow. These strategic investments not only accelerate the adoption of smart manufacturing but also position stakeholders at the forefront of industrial innovation.

Comments